Recycling & Management of Organic Waste

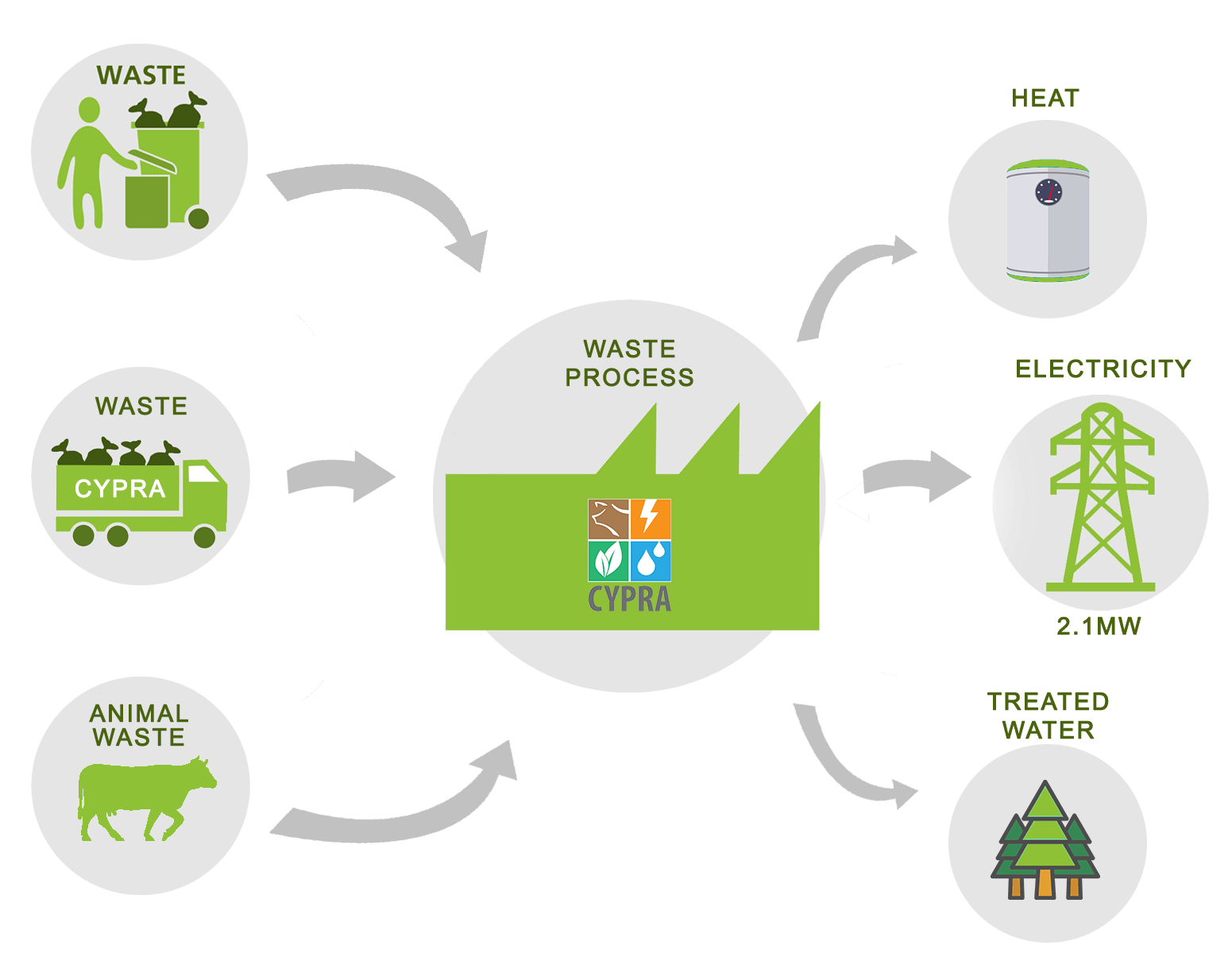

The largest Organic Waste Recycling and Management Unit in Cyprus has state-of-the-art technological infrastructure that is constantly upgraded in accordance with updated international requirements. Its operation, with aerobic and anaerobic treatment, is an important part of the circular economy and contributes catalytically to the protection of the environment, powering the production of green electricity.

Apart from the waste from the animal protein production line, the plant receives waste from pig farms, butcher shops, hotels, supermarkets, catering industries etc. from all over Cyprus. Their effective management, with the most internationally modern and environmentally beneficial and accepted methods, reduces to a minimum the wider impact on the environment from odors, pollution of aquifers, rivers and soil, visual pollution and general nuisance. This avoids a very important series of negative effects as, otherwise, all these quantities of pollutants would end up uncontrolled, burdening the environment and the quality of life of all of us.

In addition to the Group’s customer network, from time to time the plant also managed waste on behalf of the state, such as chickens that were withdrawn by the thousands in case of salmonella or Newcastle disease, as well as large volumes of other waste that the state was unable to manage. In this way, strong environmental burden factors have been drastically reduced.

In the field of Recycling, the unit, using innovative methods and technologies, manages packaging materials, glass and organic items (e.g. food) that have been withdrawn or have passed their expiration date. Thus contributing to the goals and highlighting the positive benefits of the circular economy.

In the context of the operation of the unit, high quality soil improver is produced, free from pathogens and without chemical additives. This is used for soil reinforcement within the boundaries of the Cypra facilities, with the possibility of being made available to the general public for agricultural use.

By applying an innovative total zero waste process, liquid ammonia fertilizer is produced for agricultural use during biogas production.

Water production for agricultural use and compost

As a final product of aerobic wastewater treatment of the plant, purified water suitable for use in agriculture as well as in the quarries of the area for the production of sand is produced. Read more about composting here.

Environment – Lungs of Life

This water is used, among other things, for the cultivation of fast-growing trees of the species Paulownia. These were originally imported from Australia and are now produced locally at the Cypra Group nursery. The nursery produces 3,000 – 4,000 trees every year and to date more than 10,000 trees have been planted in the area of the facilities. Thus, extensive green lungs have been created with a simultaneous strong aesthetic footprint.

In addition to this, artificial lakes have been created, with all the positive benefits to biodiversity, in an area where there is no water zone at a great distance from the plant.

2023: The truth of the numbers